Non Destructive Testing (NDT): Methods, Applications, Benefits & Industry Use Cases

Non Destructive Testing (NDT) is a important inspection technique used throughout industries to assess the integrity, exceptional, and performance of substances, additives, and structures without causing any harm. Unlike damaging trying out, NDT lets in belongings to remain operational at the same time as ensuring protection, reliability, and compliance with standards.

From production and production to oil & gasoline, aerospace, and electricity flowers, non-damaging trying out performs a critical role in preventing disasters, lowering downtime, and lengthening asset life.

What is Non Destructive Testing (NDT)?

Non-Destructive Testing refers to a group of evaluation and inspection methods used to detect defects, cracks, corrosion, thickness loss, or internal flaws with out altering the unique houses of the fabric.

The number one purpose of NDT is to ensure:

- Structural safety

- Quality control

- Regulatory compliance

- Cost-effective maintenance

Because the examined factor stays usable, NDT is right for vital and high-cost property.

Why Non Destructive Testing is Important

NDT isn’t always just about finding defects—it’s approximately preventing failures before they manifest.

Key motives why NDT is important:

- Detects hidden internal defects

- Prevents catastrophic structural screw ups

- Reduces restore and replacement expenses

- Ensures safety of people and property

- Improves product quality and reliability

Industries depend upon NDT to make informed choices about restore, substitute, or persisted use of additives.

Common Non Destructive Testing Methods

Different NDT techniques are used primarily based on fabric kind, disorder area, and inspection necessities.

1. Visual Testing (VT)

Visual checking out is the maximum primary and broadly used NDT technique. It includes examining surfaces the usage of the naked eye or tools like borescopes and cameras.

Best for:

- Surface cracks

- Corrosion

- Weld defects

- Misalignment

2. Ultrasonic Testing (UT)

Ultrasonic trying out makes use of excessive-frequency sound waves to detect inner defects and measure material thickness.

Best for:

- Internal cracks

- Thickness size

- Weld inspections

- Pipelines and stress vessels

3. Radiographic Testing (RT)

Radiographic testing uses X-rays or gamma rays to create photos of inner structures.

Best for:

- Weld best inspection

- Castings and forgings

- Internal voids and inclusions

4. Magnetic Particle Testing (MPT)

This approach is used on ferromagnetic substances to pick out surface and near-floor defects.

Best for:

- Cracks in metal components

- Weld inspection

- Shafts, gears, and rails

5. Liquid Penetrant Testing (LPT)

Liquid penetrant testing detects surface-breaking defects the usage of a penetrant liquid and developer.

Best for:

- Fine surface cracks

- Non-porous substances

- Aerospace and automotive components

6. Eddy Current Testing (ECT)

Eddy cutting-edge trying out makes use of electromagnetic induction to detect defects and degree conductivity.

Best for:

- Heat exchanger tubes

- Surface cracks

- Material sorting

Applications of Non Destructive Testing

Non-unfavorable checking out is used throughout a huge range of industries because of its reliability and performance.

Construction & Infrastructure

- Concrete structure evaluation

- Bridge inspection

- Steel reinforcement assessment

Oil & Gas Industry

- Pipeline integrity checking out

- Storage tank inspection

- Pressure vessel evaluation

Manufacturing

- Quality manage of additives

- Weld and casting inspection

- Thickness measurement

Aerospace & Aviation

- Aircraft thing inspection

- Fatigue crack detection

- Structural health monitoring

Power Plants

- Boiler tube inspection

- Turbine issue checking out

- Heat exchanger evaluation

Advantages of Non Destructive Testing

Non-destructive trying out offers a couple of blessings over conventional trying out methods:

- No damage to components

- Cost-powerful inspection

- Real-time illness detection

- Increased asset lifespan

- Improved protection standards

- Minimal downtime

These advantages make NDT the desired desire for preventive maintenance and satisfactory guarantee.

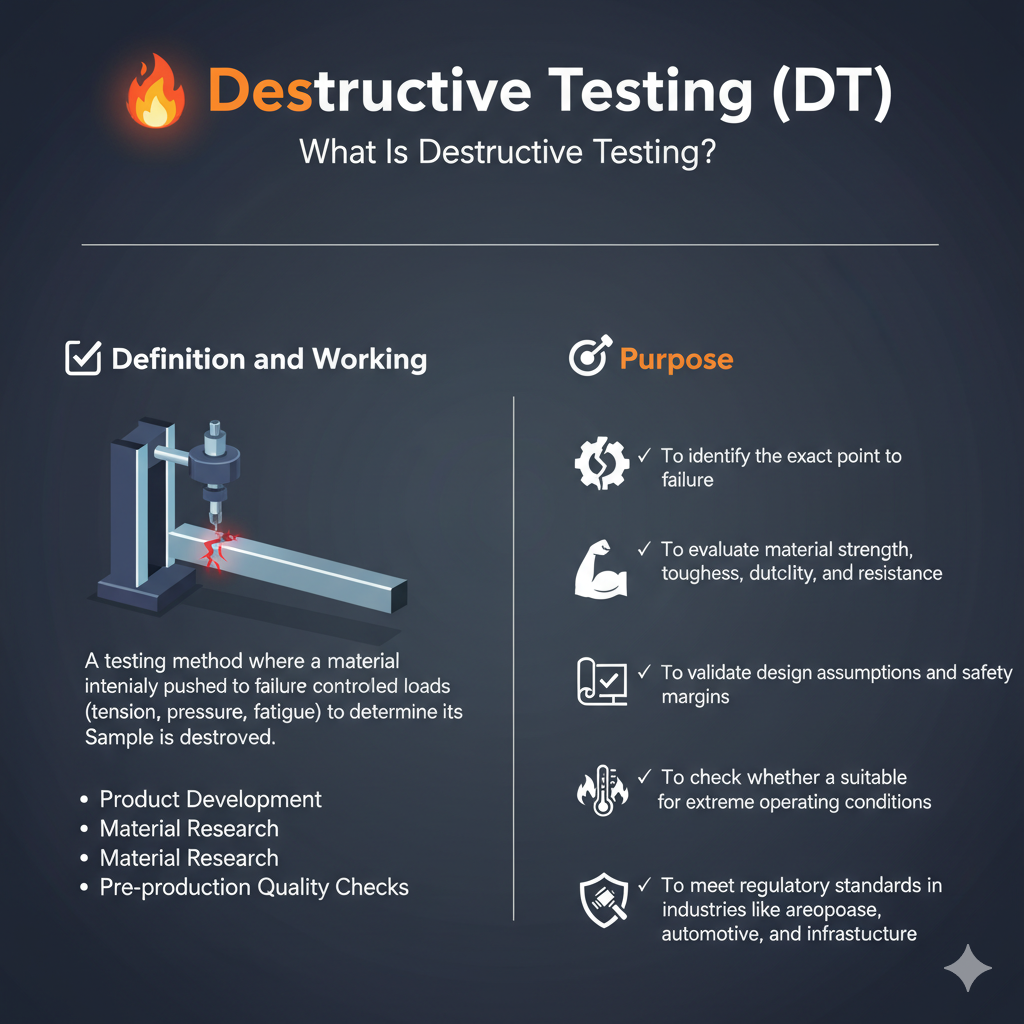

Non Destructive Testing vs Destructive Testing

Non-Destructive Testing allows materials to be inspected without causing damage, making it cost-efficient, reusable, and suitable for real-time inspection with minimal downtime. In contrast, Destructive Testing involves damaging the material to evaluate strength or limits, resulting in higher costs, no reusability, limited real-time analysis, and greater operational downtime.

| Aspect | Non-Destructive Testing | Destructive Testing |

|---|---|---|

| Damage to Material | No | Yes |

| Cost Efficiency | High | Low |

| Reusability | Yes | No |

| Real-time Inspection | Yes | Limited |

| Operational Downtime | Minimal | High |

Choosing the Right NDT Method

Selecting an appropriate NDT approach relies upon on:

- Material kind

- Nature of defect (floor or internal)

- Component geometry

- Industry requirements

- Inspection surroundings

A professional NDT assessment ensures accurate effects and compliance with safety guidelines.

Future of Non-Destructive Testing

With improvements in generation, non destructive testing is evolving hastily. Techniques like computerized ultrasonic testing, virtual radiography, drone-primarily based inspections, and AI-pushed disorder evaluation are improving accuracy and performance.

The destiny of non-detrimental checking out makes a speciality of:

- Faster inspections

- Predictive protection

- Smart tracking systems

Conclusion

Non-Destructive Testing is a cornerstone of current engineering, protection, and best assurance. By allowing correct inspection without damaging belongings, NDT allows industries reduce danger, shop costs, and keep operational excellence.

Whether it’s infrastructure, production, oil & gasoline, or aerospace, non-unfavourable testing ensures that what you can’t see doesn’t grow to be a failure you can’t manage to pay for.