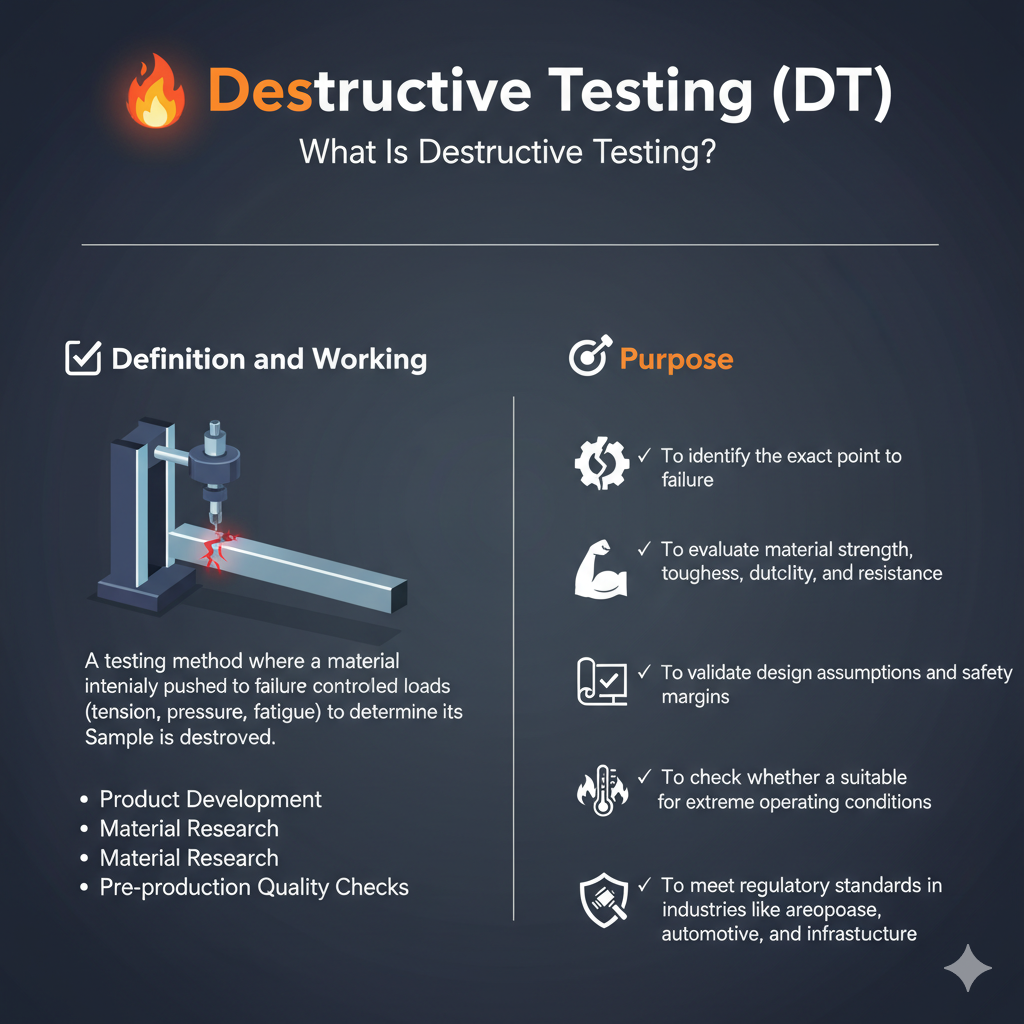

Destructive Testing: A Complete Guide to Material Strength & Performance Evaluation

Destructive testing is one of the most trusted and widely used methods in industries to evaluate the strength, durability, and performance of materials. Unlike non-destructive testing, destructive testing examines a material by pushing it to its breaking point. This helps engineers, manufacturers, and researchers understand how a material behaves under extreme loads, stresses, and environmental conditions.

Whether it is construction, manufacturing, metal fabrication, automotive, or aerospace — destructive testing plays a crucial role in ensuring safety and reliability. In this detailed guide, we explore what destructive testing is, why it is important, different destructive material testing methods, and where it is used across industries.

What is Destructive Testing?

Destructive testing (DT) is a method of evaluating the physical and mechanical properties of a material by intentionally damaging or destroying it. The aim is to determine how much load, stress, or strain a material can withstand before failure.

Unlike non-destructive testing (NDT), where the material remains intact, destructive testing permanently alters or breaks the specimen. Because of this, it provides extremely accurate data about the material’s structural integrity, strength, toughness, and behavior under different conditions.

This makes destructive testing essential for mechanical testing of materials, product design, quality control, and safety assurance.

Why is Destructive Testing Important?

Destructive testing is necessary for several reasons:

1. Determines Actual Strength

It provides real performance values such as tensile strength, yield strength, hardness, toughness, and fatigue life.

2. Ensures Product Reliability

Manufacturers rely on destructive testing to confirm whether a component will perform safely in real-world conditions.

3. Identifies Weak Points

The test helps detect flaws in raw material, manufacturing defects, or design errors.

4. Essential for Certification and Standards

Many industries require destructive testing to comply with national and international standards.

5. Supports Research and Product Development

It helps engineers understand how new materials behave under extreme loads and environments.

Types of Destructive Testing Methods

Destructive testing includes various test methods depending on the requirement. Let’s explore the most widely used destructive material testing methods.

1. Tensile Testing

Tensile testing is one of the most fundamental forms of destructive testing. In this test, a material specimen is pulled apart until it breaks.

Purpose of Tensile Test:

-

Measures tensile strength

-

Determines yield point

-

Evaluates elongation

-

Measures ductility and stiffness

It is commonly used in metals, plastics, rubber, and composite materials.

2. Hardness Testing

Hardness testing measures a material’s resistance to indentation or scratching. This helps assess wear resistance and durability.

Popular Hardness Testing Methods:

-

Rockwell Hardness

-

Brinell Hardness

-

Vickers Hardness

Hardness testing is widely used in manufacturing, machining, and metal fabrication.

3. Impact Testing

Impact testing determines the material’s ability to absorb energy under sudden loads. It is crucial for evaluating toughness.

Common Impact Tests:

-

Charpy Impact Test

-

Izod Impact Test

Impact testing helps decide whether a material can withstand harsh environmental conditions like low temperatures, vibrations, and shocks.

4. Bend Test

The bend test evaluates the ductility and flexibility of a material. It checks how much bending a material can tolerate without cracking or breaking.

Uses of Bend Testing:

-

Weld quality inspection

-

Sheet metal bending strength

-

Pipe and bar testing

This method is widely used in welding industries and structural applications.

5. Fracture Toughness Test

Fracture toughness testing evaluates a material’s resistance to crack propagation. It helps determine how cracks initiate and spread under stress.

Where it is used:

-

Aerospace

-

Pressure vessels

-

Bridges and heavy civil structures

-

Nuclear industries

The test is vital for preventing catastrophic failures in critical components.

6. Fatigue Testing

Fatigue testing measures a material’s ability to withstand repeated or cyclic loading. Many materials fail not due to a single overload but due to millions of small stress cycles.

Fatigue Testing Helps Determine:

-

Fatigue strength

-

Fatigue life

-

Crack initiation and propagation

-

Durability under vibration

Industries like automotive and aerospace rely heavily on fatigue testing.

Weld Destructive Testing

Weld destructive testing evaluates the strength, quality, and durability of welded joints by destroying a sample. Since welding is used in structures, pipelines, bridges, and machines, weld failure can be life-threatening.

Common Weld Destructive Tests Include:

-

Tensile test of welded joints

-

Bend test (face and root bend)

-

Macro etch test

-

Nick break test

-

Impact testing of weld metal

These tests help identify porosity, cracks, lack of fusion, inclusions, and other weld defects.

Destructive Testing in Civil Engineering

Destructive testing is a crucial part of ensuring structural strength in civil engineering projects.

Common DT Applications in Civil Engineering:

-

Concrete cube compression test

-

Rebar tensile test

-

Asphalt testing

-

Brick and block testing

-

Soil shear strength test

These tests ensure the durability and stability of bridges, buildings, roads, and dams.

Civil engineers use destructive testing to verify design strength, maintain safety standards, and guarantee long-term performance.

Destructive Testing in Manufacturing

Manufacturing industries rely on destructive testing to ensure product quality and performance. Whether it’s metal components, plastic parts, machinery, or automotive components — every product must meet strict quality standards.

Key Uses of DT in Manufacturing:

-

Testing batch quality of raw materials

-

Checking mechanical properties of finished goods

-

Ensuring product safety under real-world conditions

-

Verifying compliance with ISO, ASTM, and industry-specific standards

Destructive testing is a backbone of quality assurance in large-scale production industries.

Material Destruction Test vs Non-Destructive Testing

A material destruction test gives accurate mechanical properties but destroys the sample, while non-destructive testing (NDT) inspects the material without causing damage.

When to Choose Destructive Testing:

-

When precise strength values are needed

-

During research and development

-

For quality assurance during manufacturing

-

When evaluating new materials or welds

Both methods complement each other and are used together in most industries.

Advantages of Destructive Testing

-

Highly accurate results

-

Reveals true mechanical properties

-

Helps detect design or manufacturing flaws

-

Ensures long-term product reliability

-

Mandatory for safety-critical industries

Limitations of Destructive Testing

-

Sample is destroyed during testing

-

Can be costly for expensive materials

-

Time-consuming for large-scale testing

-

Not suitable for final high-value components

Despite these limitations, destructive testing remains essential across all industrial sectors.

Applications of Destructive Testing Across Industries

Destructive testing is widely used in:

Construction & Civil Engineering

To test concrete, steel, asphalt, and other building materials.

Manufacturing & Production

To ensure product quality, material consistency, and safety.

Automotive Industry

To evaluate crash resistance, fatigue life, and component durability.

Aerospace Industry

For testing aircraft components, composite materials, and weld joints.

Oil & Gas Industry

For pipeline weld testing, pressure vessel testing, and metal strength evaluation.

Research & Development

To test new materials, composites, alloys, and prototypes.

Conclusion

Destructive testing is a critical part of mechanical testing and material evaluation. It provides accurate data about material strength, durability, toughness, and performance under extreme conditions. Industries like civil engineering, automotive, aerospace, and manufacturing rely on destructive testing to maintain high safety and quality standards.

Whether it’s tensile testing, hardness testing, impact testing, bend test, fracture toughness test, fatigue testing, or weld destructive testing, each method plays a vital role in understanding and improving material performance.

Leave a Reply